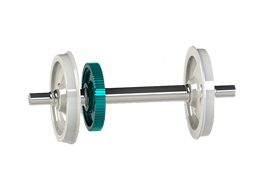

TEDRAIL Supply the wheel tyre for the tied wheel usage. Wheel tyre has been forged, then hot rolled according to the necessary wheel tyre drawing.

Dimensions could be controlled as:

Rough turned wheel tyre

Finished turned wheel tyre.

DIMENSIONS

TEDRAIL could supply wide dimension range of wheel tyre as following parameters:

| OUTSIDEDIAMETER (MM) | WIDTHOFTREAD (MM) | GAUGE (MM) | MASSWEIGHT (KG) | AXLELOAD (TON) |

| 780-1700 | 120-150 | 1000-1676 | 176-250 | 12-35 |

MANUFACTURING SPECIFICATIONS:

Following Specifications and Tolerance are available by TEDRAIL for customers ordered:

BRITISH STANDARD: BS 5892 PART 4, Railway rolling stock materials –Part 4. Specification for forged and rolled tyres.

EUROPEAN STANDARD: UIC 810-1Technical specification for the supply of rough rolled non-alloy steel tyres for tractive and trailing stock

EUROPEAN STANDARD: UIC 810-2 Technical specification for the supply of rough tyres for tractive and trailing stock - Tolerance

CHINESE RAILWAY STANDARD: TB/T 1882 Technical specification for the supply of rough rolled wheel tyres for railway rolling stock.

CHINESE RAILWAY STANDARD: GB 8602 Rough-Rolled tyres for railway

ISO 1005-1 Railway rolling stock material – Part 1: Rough-Rolled tyres for tractive and trailing stock-Quality requirements.

ISO 1005-2 Railway rolling stock material – Part 2: Tyres, wheel centers and tyred wheels for tractive and trailing stock – Dimensional, balancing and assembly requirements.

ASTM A551 Standard Specification for Carbon Steel Tires for Railway and Rapid Transit Applications

MATERIAL GRADE:

Based on our long term supply experience, TEDRAIL could supply following materials for the wheel tyres

BS 5892-4: GRADE B1N,B2N,B3N,B4N,B5E,B6E,B7E

UIC 810: B1N,B2N,B3N,B4B,B5E,B6E

ASTM A551: Class A, Class AHT, Class B, Class BHT, Class C, Class CHT, Class DHT

TB/T 1882: LG61

GB 8602: LG60,LG65

HEAT TREATMENT DELIVERY STATUS:

Hot Rolled status(U)

Normalizing(N)

Quenching and Tempering(E)

TEST CERTIFICATE

The test result are confirmed in the Certificates 3.1; 3.2 according to the EN 10204 Standard including following testing:

Chemical Analysis

Tensile Test

Impact Test (KU)

Brinell Hardness (uniformity)

Ultrasonic Flaw Detection

Magnetic Particle Inspection

Dimension and Appearance Check